Qingdao Symax Metals CO.,LTD was founded in 2000 located in Qingdao, China. It has 2 iron foundries, 2 aluminum alloy foundries, one stamoing factory and one machining shop.

In 2016 sales more than 6000 us dollars. The main products are nature gas meter parts, regulator parts, auto parts, filter parts and agriculture machine parts.The main oversea markets are us, germany, british and japan.

The main customers overseas are: ITRON, SCHROEDER INDUSTRIALS, CALGON CARBON,HYDAC AND YUASA.

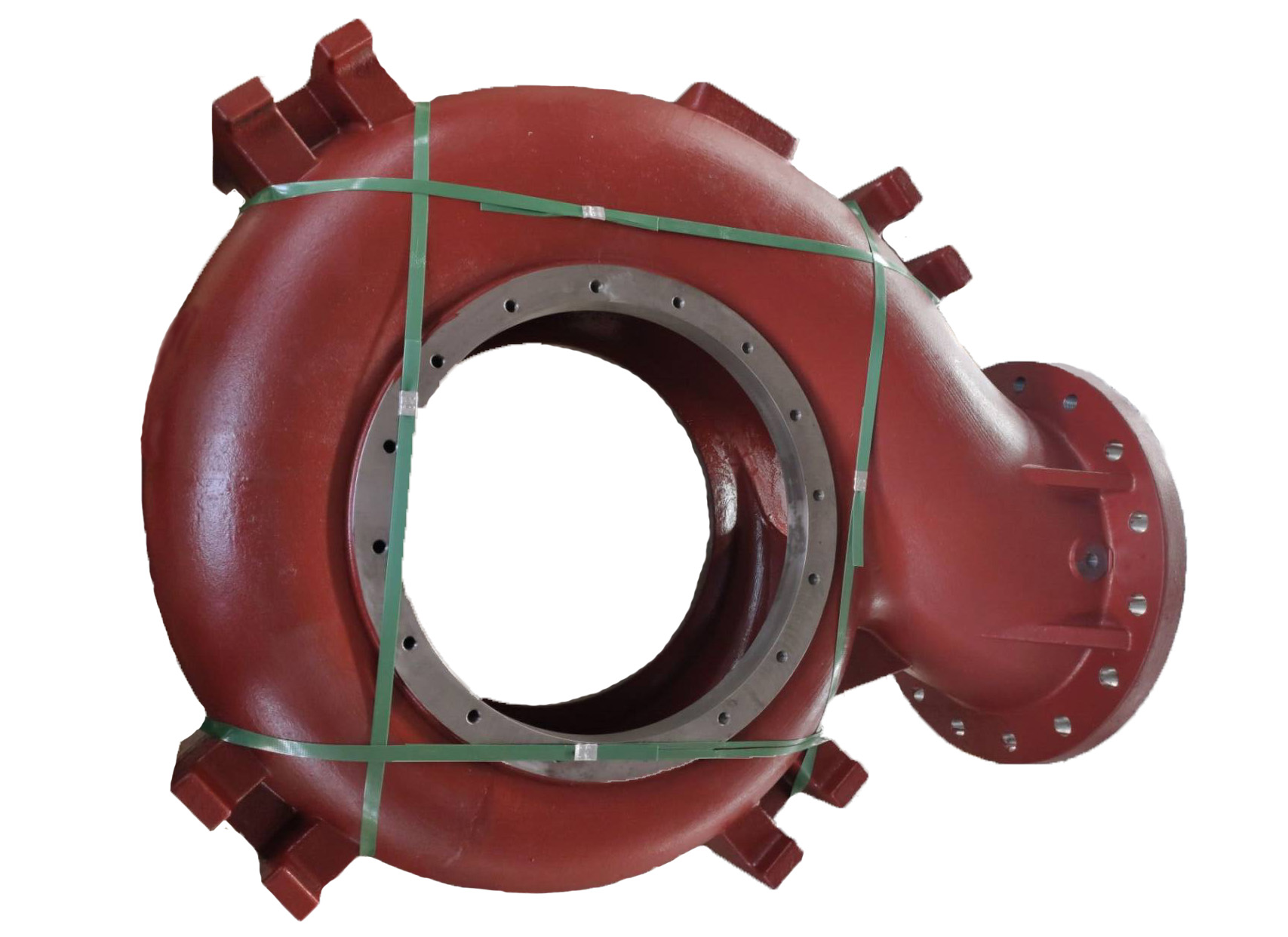

IRONCASTINGS

Material: Gray iron, Ductile iron, high chrome iron.

Standard: Gray iron :ASTM class 20, 30, 35, 45.

Ductile iron: ASTM A 536, 60-40-18,65-45-12,80-55-06.

Casting process: Green sand, resin sand, shell molding.

Equipment:

spectrumetertensile strength machine

Hardness testershot blasting machine

core making machines

The weight of our products: from 0.2KGS to 550KGS

To increase efficiency reduce the hardness of labors,increase the quality of castings, we made investment to buy more than 20 units of shell machines to do shell mould castings. We have verticla and horizontal shell making machines.We can make out more than 50 kgs castings in shell moulding process.

Aluminum Alloy Casting

Material: Aluminum alloy

Standard: ASTM A 356, 356,319, 360

Casting process: Green sand, resin sand, gravity and low pressure die casting

Equipment:

Spectrumetertensile strength,

Low pressure casting machine,

Gravity casting machines,

Casting weight: From 0.3KG to 50KGS.Wecan make high pressureparts using out gravity and low pressure die casting machines.

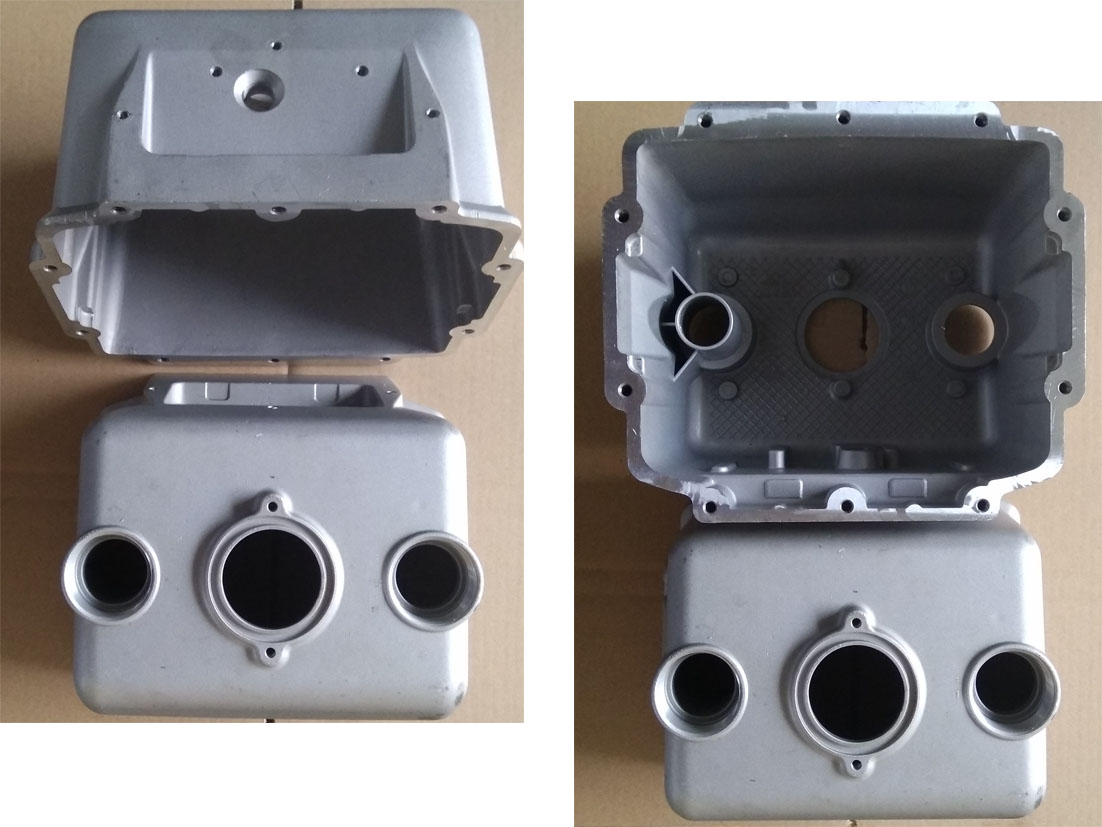

Die Castings

Material:Al alloy 380, 413,360.

Die casting machine: 160ton, 200tons, 280tons,400tons, 500tons, 650tons, 800tons, 1250tons, 2000tons.

Main products: gas meter cases, regulators, ejection pumps, auto parts.

Powder Coating

Our powder coating parts can pass at least 1000hrs salt spray test and 2000hrs salt spray testing if add anodizing before painting.

SUB-ASSMEBLY

We are doing sub-assembly to put some interior parts to save our customers cost.

Stampings

We can progressive punching machines 200ton and 80tons. We can run high qty stampings in high qualityand very competitive prices. We also have normal punching machines from 63 tons to 160 tons.